[please login to make this ad block disappear]

Articles

Design and build your own WW kayak!

|

Strategies, tools and techniques for designing and building your own kayak. |

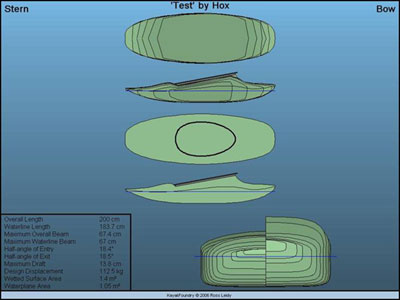

And, I did it my way :)After putting my home made whitewater kayaks on display on the Internet (Playak.com & forspaddling.com) “HOX” I’ve gotten lots of questions on how I did it. That’s why I am writing this little manual on how you can do this yourself, hoping that this will inspire more people to give it a try. I’m sure you have your own ideas on what properties your boat should have and how it is supposed to be designed. A glassfiber construction has the advantage of being lighter and stiffer than plastic boats, although they are more prone to break if you hit rocks with sections that are not designed to flex (e.g. chines and edges). Another benefit of using glass is that it’s easy to repair or redesign the boat as you get new ideas. I started with drawing the boat I wanted to build using the eminent software “Kayak Foundry” that Ross Liedy has made available for download on his web page http://www.blueheronkayaks.com/kayak/software/software.htm . Sure, it takes a little while to learn how to use and master this program... It was made for designing sea kayaks, but with some tweaking it’s possible to come up with a body suitable for a whitewater playboat. Kayak Foundry can also produce side views and cross sections on any given part of the boat.

To get you started, here is a little boat I’ve made which you can open with Kayak Foundry and use as a template: wwhomebuilt.yak (Right-click on the link and choose 'Save target as...' to save this file to your computer. You can then open the file with Kayak Foundry. Alternatively, you can download the zipped version of this file by clicking here).

The small pictures on the right show one way to do the plug and in the text below is another: KayakFoundry can draw cross sections at a distance of e.g. 10cm to use as templates for making 10cm thick foam blocks. You can cut blocks of foam with a hot wire or a band saw. Glue all the foam blocks (or thick foam sheets if you like) together using epoxy or any other glue that doesn’t degrade the foam. Do this carefully and you’ll have a good base for making your plug. It’s a good thing to make the foam blocks slightly bigger than your wanted end result as you need to shape chines etc yourself (KayakFoundry has it limitations when it comes to sharp edges). Now comes the shaping phase and it’s impossible to be too thorough with this. Shape and grind and shape and grind again until you are perfectly happy with your design. When everything looks exactly as you want it to, paint the foam model using a solvent free paint. If you are really satisfied with the finish of your model then you can cast your plug directly on the foam model, if not you can put maybe two layers of polyester plastic on it, putty and then cast.

Attention! If the surface of your plug has the quality of ordinary paint and is REALLY dry you can put two layers of release film on it and don’t bother about waxing it. Instead grind and paint the finished boat using spray paint after removing it from the mould. Ok now we have a plug to use for making the top and bottom moulds of the boat, remember that the moulds needs to be able to be removed from the plug (e.g. think of angles and corners and stuff). Put film on the plug (remember it’s better not to wax it).

Now the moulds are done. Take the plug out of the moulds and you can start fabricating your first boat out of the moulds. On my boats I have used 2 layers of 450gram weave on the deck and 3 layers (450 g) on the hull with some reinforcements where needed. It came out at about 13 kgs complete and stiffer than termoplastic boats. Always use at least 2 layers of gelcoat, even if you will paint it afterwards. During 2006 I have paddled my glass fiber boat a lot and prefer it compared to my Dagger Juice 7.1 and my WaveSport T3. It's an excellent surfer, spins well and is really fast for its length! Some guys (not me) loop in it and river running class III-IV is not a problem. It’s very forgiving! I let one of the top freestylers in Sweden try it out and his only complaint was that it was a bit hard to hold it on edge (I will fix this for next year's model ;-)

I will remake/make the next one a little narrower (1cm) and make the hull/deck slightly more rounded. You will be able to see it again here on Playak. Hogge, Sweden PS Some boats I designed this way: |

Printed templates in place  Put on strips of wood to make chines  Bottoms up!  "The skeleton" is made in plywood.  time to make a cockpit  Starting to look like something!  Top side of the plug before casting.  The inside of the deck mould.. |